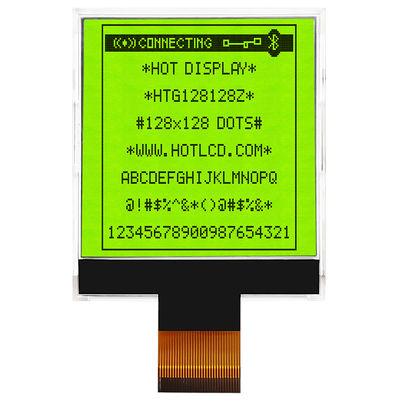

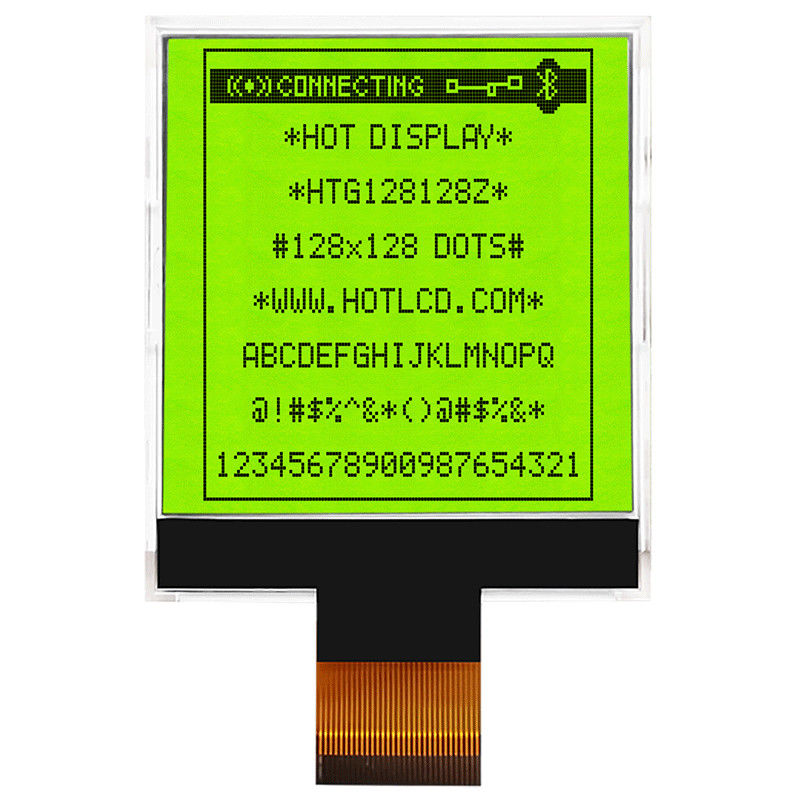

128X128 Graphic COG LCD Module SSD1848 STN-Gray Display HTG128128Z

Product Details:

| Place of Origin: | Dongguan, China |

| Brand Name: | HOTHMI |

| Model Number: | HTG128128Z |

Payment & Shipping Terms:

| Minimum Order Quantity: | 2 |

|---|---|

| Delivery Time: | 25 days |

| Payment Terms: | L/C, D/A, T/T, D/P, Western Union, MoneyGram |

| Supply Ability: | 99999 |

|

Detail Information |

|||

| Product Type: | Graphic COG | Show Contents: | 128x128 Dots |

|---|---|---|---|

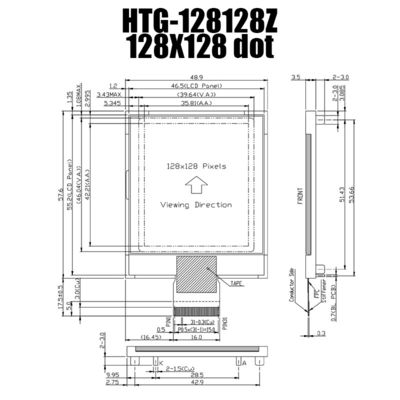

| Outline Size(mm): | 55.2x46.5x1.7 | Size Of View Window(mm): | 46.04x39.64 |

| Display Size(mm): | 42.21x35.81 | Point Spacing(mm): | 0.30x0.25 |

| Visual Angle: | 6H | Connection PIN Number: | FPC-31PIN |

| Interface Mode: | MCU/8bit | Working Temperature ℃: | -20~70 |

| Power Supply Voltage: | 3.3V | Driver Chip Model: | SSD1848 |

| High Light: | 128X128 COG LCD Module,31PIN COG LCD Module,MCU Graphic Display Module |

||

Product Description

128X128 Graphic COG LCD SSD1848 | STN-Gray Display With White Side Backlight/HTG128128Z

HTG128128Z | Monochrome Graphic COG | 128x128 Pixels | Transflective LCD | Side White Backlight | FSTN (+) Positive Gray Display

HOTLCD 128x128 graphic Chip-On-Glass (COG) Liquid Crystal Display shows blue pixels on a gray background. This transflective LCD Display is visible with ambient light or a backlight while offering a wide operating temperature range from -20 to 70 degrees Celsius. This HTG128128Z display has an optimal view of 6:00, operates at 3.3V supply voltage and is RoHS compliant.

Product parameters

| ITEM | STANDARD VALUE | UNIT |

| Number of dots | 132x64 | dots |

| Module dimension | 55.2x46.5x1.7 | mm |

| View display area | 46.04x39.64 | mm |

| Dot size | 0.33x0.28 | mm |

| Dot pitch | 0.30x0.25 | mm |

| Operating temp | -20~70 | ℃ |

| Storage temp | -30~80 | ℃ |

| Driving Method | 1/ 128 DUTY,1/ 12 BIAS,VOP= 3.3V | |

| Viewing direction | 6H o'clock | |

| Display mode | FSTN | |

| Display type | TRANSMISSIVE / NEGATIVE | |

| Driver IC | SSD1848 | |

| Backlight |

WHITE |

|

| Product application | industrial control | |

Interface Description

|

Pin No. |

Pin Name |

Function |

|

1 |

PS0 |

Interface Control. (H:Parallel; L: Serial) |

|

2 |

PS1 |

Interface Mode Control.(H:8080 or 3wire; L:6800 or 4wire) |

|

3 |

/CSB |

Chip selection input |

|

4 |

/REST |

Reset Signal |

|

5 |

RS |

Data/Command control. |

|

6 |

/WR |

Write (W/R ) control signal input. |

|

7 |

/RD |

Read (/RD ) control signal input. |

|

8~15 |

DB0~DB7 |

8-bit Date bus |

|

16 |

VDD |

Power supply voltage (3.3v) |

|

17 |

VSS |

Negative power supply(0V) |

|

18 |

VOUT |

Voltage converter input / output pin |

|

19 |

CAP4+ |

Capacitor 4 positive connection pin for voltage converter |

|

20 |

CAP4- |

Capacitor 4 negative connection pin for voltage converter |

|

21 |

CAP3+ |

Capacitor 3 positive connection pin for voltage converter |

|

22 |

CAP3- |

Capacitor 3 negative connection pin for voltage converter |

|

23 |

CAP2+ |

Capacitor 2 positive connection pin for voltage converter |

|

24 |

CAP2- |

Capacitor 2 negative connection pin for voltage converter |

|

25 |

NC |

|

|

26 |

C1+ |

Capacitor 1 positive connection pin for voltage converter |

|

27 |

C1- |

Capacitor 1 negative connection pin for voltage converter |

|

28 |

NC |

|

|

29 |

NC |

|

|

30 |

NC |

|

|

31 |

NC |

|

Absolute Maximum Ratings

| Items | Symbol | MIN. | MAX. | Unit | Condition |

|

Supply Voltage |

VDD | -0.3 | +3.3 | V | |

| VLCD | -0.3 | +15.0 | V | ||

| Input Voltage | VIN | -0.3 | VDD+0.3 | V | |

| Operating Temperature | TOP | -0 | +50 | ℃ | |

| Storage Temperature | Tst | -10 | +60 | ℃ |

All Products

| Reliability Testing | Customers can expect all production parts to meet or exceed operational requirements over temperature, humidity, and vibration. |

| Glass Cleanliness | Customers can expect glass to be protected by liners and presented mindful of cleanliness standards. This means glass will be clean of contaminants, fingerprints, and other foreign material. |

| Bezel Appearance | Bezels will be uniformly painted free of foreign materials and distracting cosmetic blemishes. Our standards maintain a clean scratch-free surface. |

| PCB Appearance | PCB’s are delivered with long-term reliability in mind. Finishes are free of bubbles, foreign contaminants, and meet all UL fire requirements. PCB materials will always be delivered within industry norms. PCB edges will be cleanly cut and void of burrs. |

| Soldering | Soldering of all leaded and SMT components is consistent in providing the mechanical security and electrical connectivity. |

| Consistency | Our manufacturing and inspection processes ensure product consistency from lot to lot. This means orders processed over the years will continually meet your expectations. We do this by exacting manufacturing specifications, with attention to detail in our processes, and by comparing to the golden units. |

| Product Integrity | Quality in product manufacturing ensures integrity in construction. Customers can expect tight assembly without worry of loose parts or missing material. Our products will meet all environmental expectations including temp, humidity, & vibration conditions. |

| Glass Color | While normal variations of glass color may occur (due to manufacturing tolerances), Newhaven Display maintains color compliance per internal approved color charts. These charts are maintained to ensure any minor glass deviations are identified and corrected as needed. |

| ESD Protection & Safety | All devices are designed and handled in consideration of ESD protection. This includes ESD-SAFE packaging within anti-static bags, wraps, and trays. Customers are reminded to always follow ESD safety to best protect the devices. |

COG LCD Displays

Available in character and graphic formats, COG (Chip-On-Glass) LCD Displays are designed without a PCB. The LCD driver/controller is bonded directly to the glass of the display. This allows COG displays to be smaller in size, more cost effective and a highly customizable display solution compared to typical LCD modules with a board.

Search Keyword: lcd 128x128, lcd 128x128, 128x128 lcd, 128x128 lcd

![]()

![]()

![]()