Optical Bonding

TFT LCD DISPLAY Panel

TFT LCD DISPLAY Panel

TFT LCD DISPLAY Panel

Standard Shipping

Shipping costs are determined by the courier system.

Timely Delivery

Track your order in real-time

Low Price Guarantee

We offer competitive prices

Quality Guarantee

We Guarantee Our Products

HOTHMI is an LCD display manufacturer with over 21 years of history. We provide comprehensive services for your HMI display solutions.

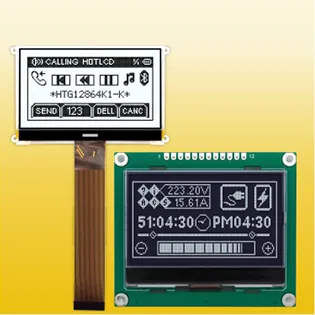

check Multiple Backlight Colors Available

check High Reliability

check Customization Supported