What are COG LCD displays?

COG LCD (Chip-on-Glass LCD Display) is a liquid crystal display technology that directly bonds the driver chip onto the glass substrate. By integrating the IC chip directly onto the LCD glass, COG LCD display technology achieves a thinner, more compact, and more reliable display module structure, making it particularly suitable for electronic products with extremely high demands on space, weight, and reliability. Compared to traditional COB (Chip-on-Board) packaging, COG LCD displays offer superior performance in terms of integration, connection stability, and anti-interference capabilities.

What types of COG LCD displays does HOTHMI offer?

We offer COG LCD displays with common resolutions ranging from 16×2 to 320×240. They support SPI, I²C, and 8-bit parallel interfaces, and are compatible with mainstream MCUs. Different modes are available such as STN-YG positive, STN-Blue negative, FSTN-Gray positive, DFSTN negative, and VA mode. A wide variety of backlight colors are available, including yellow-green, green, white, and orange. These can be combined to produce over 48 different display effects.These character LCD displays can be made to multiple viewing angles such as 6:00, 12:00, 3:00, and 9:00 o’clock;

Showing all 3 results

COG LCD display Product-related videos:

What are the product features and advantages of COG LCD displays?

- Thin and compact: Thanks to the elimination of external driver boards and connectors, COG LCD displays typically have a module thickness that is 30%-50% less than traditional modules of the same size. This is crucial for devices where internal space is at a premium and can be a deciding factor in the success of industrial design. Its compact structure also allows for more flexible installation options.

- High reliability: The chip is directly connected to the glass, reducing contact points and improving vibration and shock resistance, making it suitable for harsh environments.

- Low power consumption: Low power consumption is an inherent advantage of COG LCD displays. Their driver IC architecture is specifically optimized for low power consumption, combining static driving with low-voltage operation. Designed with standby, sleep, and deep sleep modes, the current can be reduced to microampere (μA) levels during static display, for example, approximately 100 μA, or even lower. This allows IoT sensors, remote meters, and portable medical devices using COG LCD displays to have battery lives measured in months or even years.

- Fast response speed:Short signal transmission path improves display refresh rate and response speed.

- Strong anti-interference ability: The chip has built-in shielding and filtering design, suitable for industrial applications with complex electromagnetic environments.

- Sunlight readable: High-contrast COG LCDdisplay modes, such as STN (Super Twisted Nematic), FSTN (Film Compensated Super Twisted Nematic), or VA (Vertical Alignment) modes, offer higher native contrast ratios than ordinary TN screens. Their reflective or transflective design characteristics allow them to operate reliably in outdoor POS terminals, automotive displays, and industrial handheld terminals without the need for additional sunshades.

- Long-term stability: Mature materials and processes are suitable for the design and manufacturing of long-life cycle products.

How are COG LCD displays manufactured?

The essence of COG LCD displays is the successful application of a highly integrated semiconductor packaging technology in the field of liquid crystal displays. Its full name is “Chip On Glass,” meaning the chip is directly bonded onto the glass. This process completely revolutionized the assembly logic of traditional display modules.

- Step 1:Substrate Preparation – The precision canvas for COG displays. The manufacturing of COG LCD displays begins with its foundation – an ultra-thin, highly flat glass substrate.

- Step 2:Chip Mounting – The core that gives the display its “intelligence.” Precisely placing the driver IC chip onto the prepared glass substrate is crucial for the functionality of the COG LCD display.

- Step 3:Precision Bonding – This is the most technically demanding step in COG LCD display production, permanently establishing the connection between the chip and the glass.

- Step 4:Encapsulation Protection – A barrier ensuring long-term reliability. After bonding is complete, the fragile connection points need to be protected. This is the final critical process to ensure the stable operation of the COG LCD display in harsh environments.

Where can Chip on Glass display modules be used?

Chip on Glass display modules are used in applications where compact size, low cost, high reliability, and a slim profile are critical.

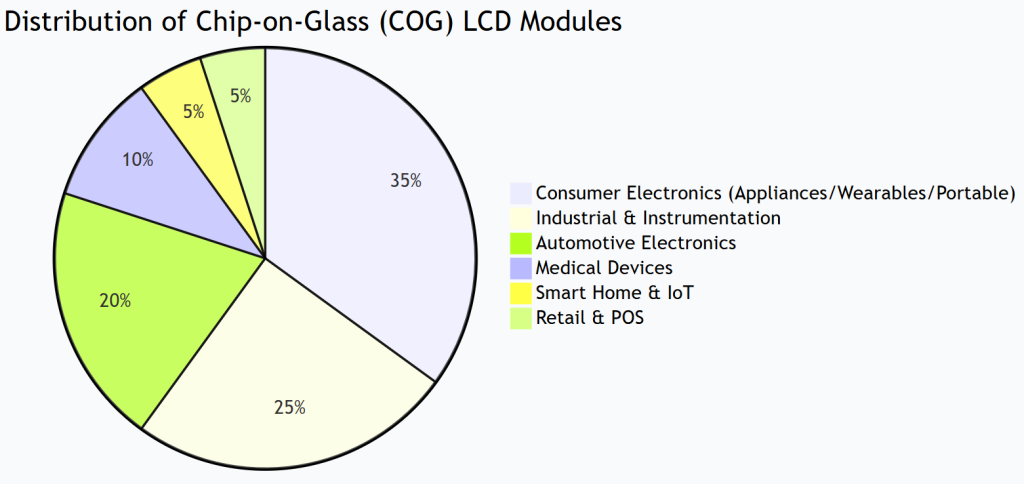

From the chart, we can see that Chip on Glass display modules have a wide range of applications in various fields, including consumer electronics (such as smart home control panels, fitness equipment displays, and portable tools), industrial and instrumentation (such as PLC panels, instruments, and test equipment), automotive electronics, medical devices (such as portable monitors, diagnostic equipment, and infusion pump panels), and smart home devices.

What customized services can HOTHMI provide for Chip on Glass LCD Modules?

Since 2004, HOTHMI has been focusing on the research, development, and mass production of COG LCD displays, making it an early pioneer and continuous innovator in this field.

1.What are the customization advantages of Chip on Glass LCD Modules compared to TFT LCD modules?

| Comparison Item | Chip on Glass LCD Modules | TFT LCD Module |

| NRE (Non-Recurring Engineering) Fee | Very low, approximately $1,000 – $5,000 | Very high, typically $100,000 – $300,000 or more |

| MOQ (Minimum Order Quantity) | Very low, mass production possible from 1,000 pieces | Very high, typically starts at 100,000 pieces (100K) |

| Customization Cycle | Short, typically 4- 6weeks | Long, typically 4 – 6 months or longer |

| Customization Flexibility | High, flexible adjustments in size, shape, display segmentation, backlight, interface, etc. | Low, primarily limited to adjustments in standard sizes and resolutions, with extremely high mold opening costs |

From the chart,we can see that :Chip on Glass LCD Modules offer significantly lower NRE costs, smaller MOQs, shorter lead times, and greater design flexibility, making them ideal for low-to-mid volume custom projects. In contrast, TFT LCD modules require much higher upfront investment and order quantities, have longer development cycles, and are more suitable for high-volume standardized applications.

2.What customized services can HOTHMI provide to Chip on Glass LCD Modules?

Custom COG LCD display (Chip on Glass LCD Modules) capabilities include:

- Physical characteristics: Any Chip on Glass LCD Modules size, aspect ratio, and custom shapes (circular, polygonal, with notches).

- COG LCD display (Chip on Glass LCD Modules) content: Fully customizable segment codes, icons, and dot matrix area layouts.

- Optical performance: Positive/negative display modes, different polarizer colors, transflective/transmissive/reflective modes, and wide operating temperature range (-30℃ to +85℃ or even wider).

- Electrical and mechanical: Specific interface protocols (I2C, SPI, parallel), connector types, and COG LCD display (Chip on Glass LCD Modules) backlight color, brightness, and uniformity requirements.

This “small batch, multi-batch, fast response” COG LCD display (Chip on Glass LCD Modules) customization capability provides unprecedented freedom for innovation for startups, research projects, professional equipment manufacturers, and brands seeking product differentiation. It makes it possible to create a “unique face” for a product within a limited budget.

FAQ about COG LCD display

Q1: Does the COG LCD display support color display?

A: Yes, COG LCD displays can achieve color display through integrated color filters, but they are typically limited to static or low-refresh-rate color segment displays or simple matrix displays.

Q2: How are the lifespan and reliability of Chip on Glass LCD Modules guaranteed?

A: Chip on Glass LCD Modules utilize direct chip-on-glass bonding and epoxy resin encapsulation protection, avoiding connector oxidation and solder fatigue issues. They can operate stably within a wide temperature range of -30℃ to 80℃, with a typical lifespan exceeding 50,000 hours.

Q3:What should I do if my COG LCD display shows incomplete or garbled characters?

When the COG LCD display exhibits display abnormalities, first check if the power supply voltage is stable, and then verify that the initialization sequence is correct. Ensure that the data format sent to the COG LCD display matches the configuration, and check that the timing parameters meet the requirements specified in the datasheet.

Q4:What should I do if my COG LCD display shows incomplete or garbled characters?

A:This is an inherent characteristic of liquid crystal materials. Choosing a specialized wide-temperature range Chip on Glass LCD Modules can improve low-temperature performance. Additionally, consider adding a heating circuit to the COG LCD display or incorporating a low-temperature compensation algorithm in the software.

Q5:Do I need to purchase a separate control chip for the COG LCD display?

A:NO,HOTHMI provides integrated COG LCD displays with the glass and driver IC already bonded together, eliminating the need for developers to purchase chips separately. We will provide the driver chip datasheet and sample code.